Application and development of sodium dihydrogen phosphate dihydrate in industrial field

Sodium Dihydrogen Phosphate Dihydrate in Industrial Applications

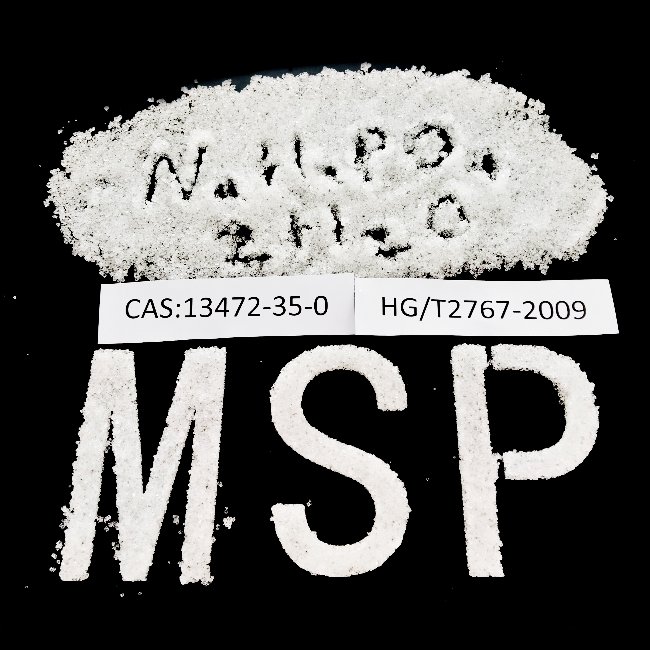

1. Basic Information and CAS

Sodium dihydrogen phosphate dihydrate has the chemical formula NaH₂PO₄·2H₂O. It is a hydrated form of sodium dihydrogen phosphate and plays a significant role in industrial production. Its CAS number is 13472 - 35 - 0.

2. Physical Properties

2.1 Appearance and State

Sodium dihydrogen phosphate dihydrate usually appears as colorless transparent monoclinic crystals or white crystalline powder. This crystalline form provides certain stability during storage and transportation, and it is also easy to identify and handle in industrial applications.

2.2 Solubility

It has good water solubility and can dissolve rapidly in water. During the dissolution process, ionization occurs, generating hydrogen ions (H⁺) and making the solution acidic. This acidic property is of great significance in many industrial applications, especially in chemical reactions or processes that require an acidic environment. However, it has relatively low solubility in organic solvents.

2.3 Hygroscopicity and Stability

Sodium dihydrogen phosphate dihydrate has a certain degree of hygroscopicity and tends to absorb moisture in a humid environment. Under normal temperature and pressure, it is relatively stable. However, under high - temperature conditions, it gradually loses its crystallization water. Its melting point is relatively low, approximately 60 °C. When the temperature exceeds the melting point, physical state changes will occur, which requires special attention during heating or drying processes in industrial production.

3. Industrial Uses

3.1 Electroplating Industry

3.1.1 pH Regulation and Buffering

In the electroplating process, the pH value of the electroplating solution needs to be precisely controlled. Sodium dihydrogen phosphate dihydrate can be used as a pH regulator and buffer in the electroplating solution to maintain the stability of the acidity and alkalinity of the electroplating solution. Different metal electroplating processes (such as nickel, chromium, zinc, etc.) have specific pH requirements. By adding sodium dihydrogen phosphate dihydrate, the electroplating reaction can be ensured to be carried out in a suitable acidic environment, enabling the uniform deposition of metal ions and improving the quality and appearance of the electroplated layer.

3.1.2 Improving Electroplating Efficiency

It interacts with metal ions in the electroplating solution to form complexes, which helps to increase the deposition rate and efficiency of metal ions on the cathode surface, reduce the occurrence of side reactions, thereby improving the electroplating production efficiency and reducing production costs.

3.2 Chemical Synthesis Field

3.2.1 As a Raw Material

As an important raw material in chemical synthesis, sodium dihydrogen phosphate dihydrate participates in the production of various phosphate - based compounds. For example, in the preparation of trisodium phosphate, sodium pyrophosphate, etc., it provides phosphate ions and sodium ions for chemical reactions to synthesize target phosphate products. These products have extensive applications in industries such as detergents, ceramics, and glass.

3.2.2 Catalytic Role

In some organic synthesis reactions, sodium dihydrogen phosphate dihydrate can act as a catalyst or a part of a catalyst. It can provide an acidic catalytic environment to promote the progress of the reaction. For example, in some esterification reactions and condensation reactions, it helps to increase the reaction rate and product yield, bringing convenience to organic chemical production.

3.3 Detergent Industry

3.3.1 Water Softening

In detergent formulations, sodium dihydrogen phosphate dihydrate is an effective water - softening agent. It reacts with calcium (Ca²⁺) and magnesium (Mg²⁺) ions in hard water to form insoluble calcium phosphate and magnesium phosphate precipitates, thereby reducing the hardness of the water. This prevents hard - water ions from combining with surfactants in the detergent to form scale, ensuring that the detergent can exhibit good detergency even in hard - water conditions.

3.3.2 pH Stabilization and Synergistic Effect

Maintaining the stability of the pH value of the washing solution is another important function of sodium dihydrogen phosphate dihydrate. It can act in synergy with other components in the detergent to keep the washing solution at an appropriate acidity - alkalinity during the washing process, ensuring that the active components of the detergent perform optimally and improving the washing effect and prolonging the service life of the detergent.

3.4 Water Treatment Industry

3.4.1 Water Quality Adjustment and Anti - scaling

In industrial circulating water and boiler water treatment, sodium dihydrogen phosphate dihydrate is used to adjust the water quality's acidity - alkalinity and control the phosphate content in the water. An appropriate amount of phosphate can form a protective film on the surface of metal pipes and equipment, inhibiting the scaling of calcium, magnesium, and other metal ions in the water. At the same time, it can slow down the corrosion rate of metals, prolong the service life of the equipment, and ensure the stable operation of industrial production.

3.4.2 Scale Removal Application

For industrial equipment that has already developed scale, sodium dihydrogen phosphate dihydrate can be used as a scale remover. It reacts with calcium and magnesium salts in the scale to convert the scale into soluble or easily removable substances, restoring the heat - exchange efficiency and normal operation state of the equipment and reducing energy consumption and equipment failures caused by scale problems.

4. Instructions for Use

4.1 Electroplating Industry Use

4.1.1 Preparation of Electroplating Solution

Determine the amount of sodium dihydrogen phosphate dihydrate according to the type of electroplated metal and process requirements. When preparing the electroplating solution, slowly add an appropriate amount of sodium dihydrogen phosphate dihydrate to deionized water and use a stirring device (such as a mechanical stirrer or magnetic stirrer) to stir until it is completely dissolved. Then, add other components of the electroplating solution according to the formula, such as main salts, complexing agents, and additives, and finally make up the volume with deionized water to the specified volume. During the entire process, pay attention to controlling the stirring speed and temperature to avoid local overheating or solution splashing and prevent impurities from mixing into the electroplating solution.

4.1.2 Maintenance during the Electroplating Process

During the electroplating process, regularly use a precision pH meter to detect the pH value of the electroplating solution. If the pH value deviates from the set range, an appropriate amount of sodium dihydrogen phosphate dihydrate solution can be added for adjustment. At the same time, closely observe the quality of the electroplated layer. If there are abnormal conditions such as uneven gloss, pits, or peeling of the electroplated layer, immediately conduct a comprehensive analysis of the electroplating solution, including the concentration of sodium dihydrogen phosphate dihydrate, impurity content, and changes in other components. Take corresponding adjustment measures, such as supplementing or adjusting the amount of sodium dihydrogen phosphate dihydrate and replacing part of the electroplating solution components.

4.2 Chemical Synthesis Industry Use

4.2.1 When Used as a Raw Material

Accurately weigh sodium dihydrogen phosphate dihydrate according to the synthesis route and chemical reaction equation of the target product. When adding it to the reaction system, pay attention to controlling the reaction conditions, such as temperature, pressure, and reaction time. If the reaction has requirements for the pH value of the solution, adjust and monitor it in advance during the reaction process. At the same time, ensure that sodium dihydrogen phosphate dihydrate is thoroughly mixed in the reaction system through stirring or other appropriate mixing methods to ensure the smooth progress of the reaction and improve the yield and quality of the product.

4.2.1 When Used as a Catalyst

Determine the optimal dosage range of sodium dihydrogen phosphate dihydrate as a catalyst through experiments. During the reaction process, maintain the stability of the reaction conditions, especially factors such as temperature and water content in the reaction system, because these factors may affect the activity of the catalyst. After the reaction is completed, if catalyst recovery is required, select an appropriate recovery method based on the differences in physical and chemical properties between sodium dihydrogen phosphate dihydrate and other substances in the reaction system, such as filtration and extraction.

4.3 Detergent Industry Use

4.3.1 Addition in Detergent Formulation

When designing a detergent formulation, determine the addition ratio of sodium dihydrogen phosphate dihydrate according to the type of detergent (such as powdered detergent, liquid detergent, etc.), the water hardness of the target market, and the expected washing effect. For powdered detergents, sodium dihydrogen phosphate dihydrate can be thoroughly mixed with other solid raw materials through a mixing device. For liquid detergents, first dissolve sodium dihydrogen phosphate dihydrate in a part of the solvent (such as deionized water) and then mix it evenly with other liquid components. During the mixing process, pay attention to avoiding local over - concentration, which may lead to caking or stratification.

4.3.2 Quality Control and Adjustment

Conduct quality tests on the produced detergent products, including detergency tests in simulated hard water of different hardnesses and actual use environments, as well as pH stability tests. If the test results show poor washing effect or unstable pH value, adjust the amount of sodium dihydrogen phosphate dihydrate or the overall formulation of the detergent. At the same time, ensure the quality stability of different batches of sodium dihydrogen phosphate dihydrate to avoid quality problems in detergent products caused by fluctuations in raw material quality.

4.4 Water Treatment Industry Use

4.4.1 Water Treatment Dosing Operation

In industrial circulating water and boiler water treatment, first conduct a detailed water quality analysis of the raw water, including hardness, acidity - alkalinity, dissolved oxygen, metal ion types and contents, etc. Based on the analysis results and treatment objectives, calculate the dosing amount of sodium dihydrogen phosphate dihydrate. It can be added to the water either by an automatic dosing device or manual dosing. For automatic dosing devices, regular calibration and maintenance are required to ensure the accuracy of the dosing amount. For manual dosing, strictly follow the operating procedures to avoid dosing errors. During the dosing process, pay attention to evenly dispersing sodium dihydrogen phosphate dihydrate in the water to prevent local over - concentration.

4.4.2 Scale Removal Operation Points

When using sodium dihydrogen phosphate dihydrate for scale removal, prepare a suitable concentration of scale - removal solution according to the nature of the scale (such as calcium carbonate scale, calcium sulfate scale, etc.), its thickness, and the equipment's material and structure. For small - sized equipment, the immersion method can be used for scale removal, that is, soaking the equipment in the scale - removal solution for a certain period of time. For large - sized and complex equipment (such as pipeline systems, heat exchangers, etc.), the circulation - flushing method can be used for scale removal, allowing the scale - removal solution to circulate within the equipment. During the scale - removal process, pay attention to controlling the temperature, flow rate, and treatment time of the scale - removal solution to avoid corrosion or other damage to the equipment. After scale removal is completed, thoroughly rinse the equipment with clean water to remove residual scale - removal solution.

5. Development Advantages

5.1 Chemical Property Advantages

5.1.1 Acidic Regulation Function

Sodium dihydrogen phosphate dihydrate is acidic after dissolution, and its acidity can be adjusted within a certain range. This provides great convenience for industrial processes that require specific pH values. Whether in electroplating, chemical synthesis, detergent, or water treatment industries, precise acidic regulation is crucial for product quality and process efficiency.

5.1.2 Reaction Characteristics with Metal Ions

It can react with various metal ions to form precipitates or complexes. In applications such as water softening, electroplating, and water treatment, this interaction with metal ions can effectively solve problems caused by metal ions, such as scaling and reduced electroplating quality, thereby improving the quality and efficiency of industrial production.

5.2 Wide and Mature Applications

Sodium dihydrogen phosphate dihydrate has long - term and mature applications in multiple industrial fields, giving it a stable position in the industrial market. Each industry has an in - depth understanding of its performance and usage methods, forming a complete application system. This broad application foundation reduces the entry barrier for new users and also provides strong support for its continuous development.

5.3 Reasonable Cost - Benefit

From the perspective of production cost, the production process of sodium dihydrogen phosphate dihydrate is relatively mature, and the raw material sources are extensive, so the price is relatively reasonable. In industrial applications, it can effectively improve product quality and production efficiency and reduce cost increases caused by water quality problems, equipment corrosion, and poor washing effect. For example, it can extend the service life of equipment in water treatment and improve the detergency of detergents, bringing considerable economic benefits to enterprises.

6. Future Prospects

6.1 Green Development Driven by Environmental Protection Requirements

With the continuous improvement of environmental protection awareness and the increasingly strict environmental protection regulations, the demand for green chemical products in the industrial field will continue to increase. For the production and use of sodium dihydrogen phosphate dihydrate, future development will be more environmentally friendly. On the one hand, more environmentally friendly production processes will be developed to reduce waste emissions and energy consumption during the production process. On the other hand, more environmentally friendly usage methods will be explored in applications. For example, low - phosphorus or phosphorus - free substitutes will be developed for use in detergents, and potential environmental impacts in water treatment will be reduced to meet environmental requirements.

6.2 Research and Development of High - performance Products to Meet High - end Demands

The continuous progress of industrial technology will further increase the performance requirements for sodium dihydrogen phosphate dihydrate. In the electroplating industry, with the development of high - end manufacturing industries such as the electronics industry, the quality requirements for electroplated layers are becoming higher and higher. This will drive the development of sodium dihydrogen phosphate dihydrate towards high - purity and high - performance directions to meet more precise electroplating requirements. In the chemical synthesis field, the performance requirements for catalysts, such as activity and selectivity, are also increasing. Sodium dihydrogen phosphate dihydrate is expected to develop more efficient catalytic products through modification or compounding methods.

6.3 Intelligent Application to Improve Industrial Efficiency

With the improvement of industrial automation and intelligence levels, the intelligent control of sodium dihydrogen phosphate dihydrate in industrial applications will become a future development trend. In electroplating, water treatment, and other industries, sensor technology will be used to monitor key parameters (such as pH value, ion concentration, temperature, etc.) in real - time. Combined with intelligent algorithms and automated control systems, precise dosing of sodium dihydrogen phosphate dihydrate and automatic optimization of process parameters will be achieved. This can not only improve production efficiency and product quality but also reduce human operation errors and labor intensity, bringing greater benefits to industrial production.