Jan 14, 2025

Viewed: 154

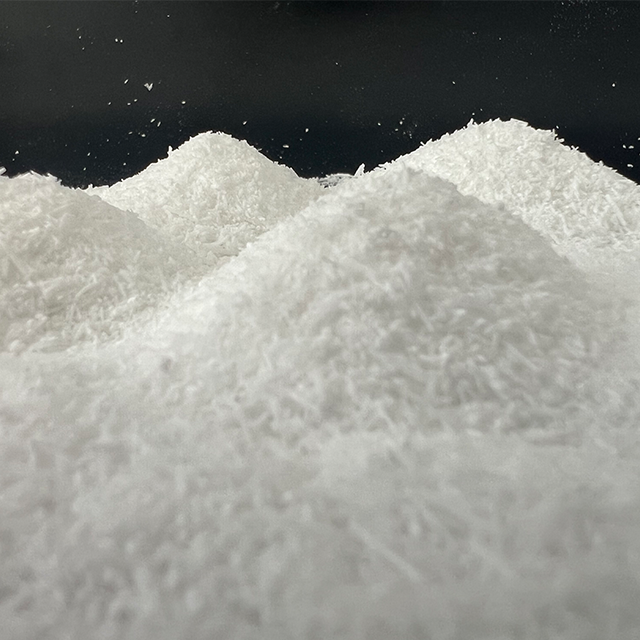

Sodium dihydrogen phosphate dihydrate

Sodium dihydrogen phosphate dihydrate

Sodium dihydrogen phosphate dihydrate is a white crystalline powder or granule, relative density 2.04, melting point 60 ℃. 100 ℃ below the heating, can be dissolved in the water of crystallization to form a hydrate.Sodium dihydrogen phosphate dihydrate has a wide range of applications, can be It can be used as analytical reagent, buffer and water softener, and used for bacterial culture; it can also be used as quality improver, which can improve the complex metal ions of food, pH value, increase ionic strength, and improve the adhesion and water-holding capacity of food; it can also be used as feed phosphorus supplement additive.

Sodium dihydrogen phosphate dihydrate has the following main production processes:

1. Extraction method

The use of extractant and sodium chloride (or sodium hydroxide), phosphorus wet process acid solution for homogeneous reaction, the extractant and the solution of Cl- combination to form the organic phase, H2PO4 and the solution of Na + to form a solution of sodium dihydrogen phosphate, through the concentration, cooling and crystallization of the sodium dihydrogen phosphate products; the organic phase into the ammonia to get regeneration of the extractant and ammonium chloride solution, extractant regeneration after recycling. Wet process phosphoric acid, sodium chloride as raw materials, the use of continuous extraction method to obtain industrial-grade sodium dihydrogen phosphate, and continuous mode test research, the test obtained by the quality of sodium dihydrogen phosphate products can meet the industrial-grade sodium dihydrogen phosphate index requirements. Using industrial wet-process phosphoric acid and sodium hydroxide as raw materials and tributyl phosphate (TBP) + kerosene (diluent) as extractant, disodium phosphate was prepared by combining extraction, back-extraction and crystallization processes. Under the optimized extraction and crystallization conditions, the yield of phosphorus pentoxide loaded in the extraction phase could reach 95.0% after three-stage extraction, and the purity (mass fraction) of disodium phosphate could reach more than 99.3%, and the impurities such as Fe, As, and Pb were all removed at a high rate. The extraction method is currently in the experimental research stage and has not been used in industrial production.

2. Compound decomposition method

Sodium dihydrogen phosphate is prepared by compounding calcium phosphate and sodium sulfate, and the yield of compounding method is only 79.1%. This process has the advantages of high product purity, simple process flow and easy operation, but the yield is low and the required raw materials have high purity.

3. Neutralization method.

3.1, disodium phosphate neutralization method will be dodecahydrate disodium phosphate according to the ratio of 3:2 dissolved in water, filtered to remove insoluble matter, and then add the filtrate to the neutralizer, slowly add phosphoric acid under stirring to carry out the neutralization reaction, control the pH value of 4.2 ~ 4.6, the reaction solution by evaporation and concentration to the formation of crystalline film until the crystalline membrane is cooled, crystallization, centrifugal separation, to get disodium phosphate dihydrate. Then dried at 100 ℃ to produce anhydrous sodium dihydrogen phosphate finished product.

3.2 Soda ash or caustic soda neutralization method will be sodium hydroxide or soda ash into the reaction kettle, add water to dilute to a certain concentration, stirring to add hot phosphoric acid, the end point of the reaction is controlled in the pH value of 4.2 ~ 4.6, evaporation and concentration, cooled to 60 ~ 70 ℃ precipitation of crystals, centrifugal separation, to get dihydrate sodium dihydrogen phosphate. Then dried by airflow, anhydrous sodium dihydrogen phosphate finished product. The process of neutralization method is relatively simple, but the production process has high energy consumption and high pollution.

3.2.1, sodium bicarbonate and phosphoric acid reaction method will gradually add phosphoric acid to the sodium bicarbonate solution, the reaction to produce sodium dihydrogen phosphate, carbon dioxide and water. This method has a faster reaction speed, but the reaction product is less pure and requires subsequent purification.

H3PO4+NaHCO3→NaH2PO4+CO2+H2O.

3.2.2 Sodium hydroxide and phosphoric acid reaction method

Phosphoric acid is gradually added to the sodium hydroxide solution, the reaction generates sodium dihydrogen phosphate and water. The reaction conditions of this method are milder, and the reaction product is more pure, but the reaction speed is slower, and a longer reaction time is needed.H3PO4+NaOH→NaH2PO4+H2O.

Sodium dihydrogen phosphate dihydrate, should be stored in a cool, ventilated, dry, clean, non-toxic warehouse, should not be stacked in the open air.

sodium dihydrogen phosphate dihydrate synonym

sodium dihydrogen phosphate uses

sodium dihydrogen phosphate other name

sodium dihydrogen orthophosphate synonyms

sodium dihydrogen phosphate price

sodium hydrogen phosphate dihydrate formula

sodium dihydrogen phosphate dihydrate formula

sodium dihydrogen phosphate dihydrate merck