Products

High Performance Acoustic Panels For Noise Reduction And Echo Control

Acoustic panels

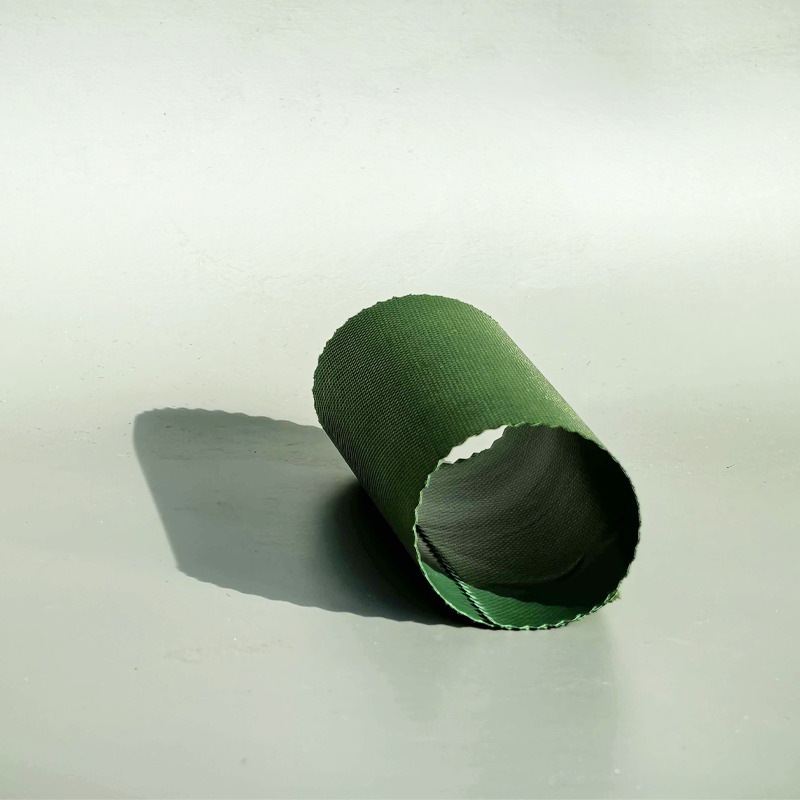

Reinforced Strong Coated Fabric Offering Long-Lasting Wear And Stability

coated fabric

High-quality potassium hydroxide (KOH), a strong alkali, is suitable for chemical applications.

Water Treatment Chemical

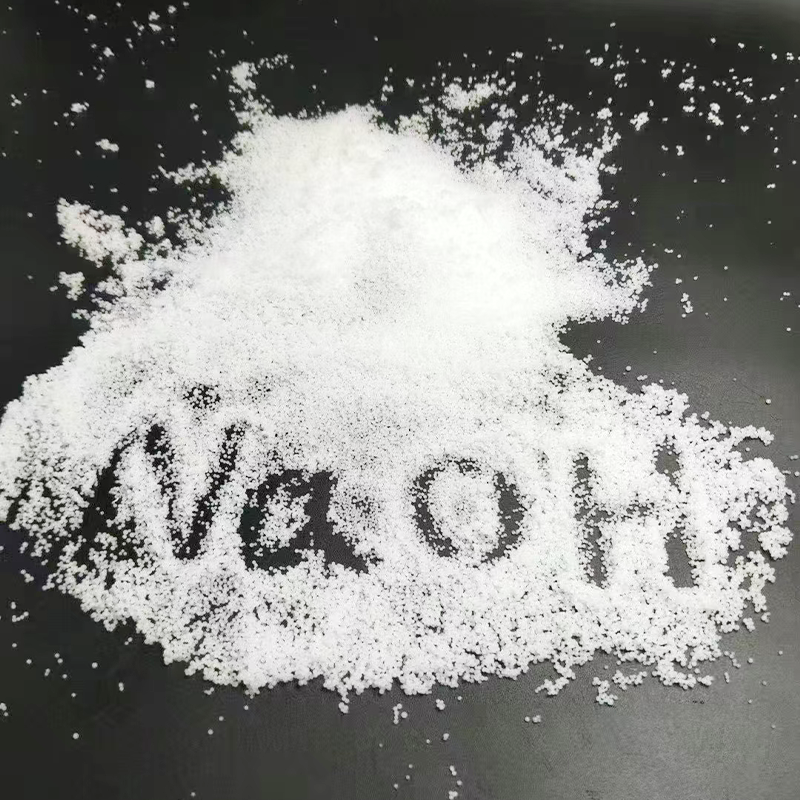

Caustic Soda 99% Sodium Hydroxide Pellets – Premium Quality Chemical Raw Material

Water Treatment Chemical

zinc oxide

zinc oxide

Styrene acrylic emulsion

Emulsion series products

High Quality Granule Water Purification 25kg Sodium Dichloroisocyanurate SDIC Dihydrate 56%

Water Treatment Chemical

Zinc Oxide

Zinc Oxide

Carboxymethyl cellulose CMC

Polyester fiber

Redispersible Polymer Powder

Polyester fiber

Learn more